Applications

- Home

- Applications

Industrial Applications

SCIENCE & HEALTHCARE SECTOR

Apron, Partitions, Shoe Cover, Gowns, Pillow Covers, Bed Sheets, etc,.

BATTERY INDUSTRY

Separators

AGRICULTURE SECTOR

Crop Covers

AUTOMOBILE INDUSTRY

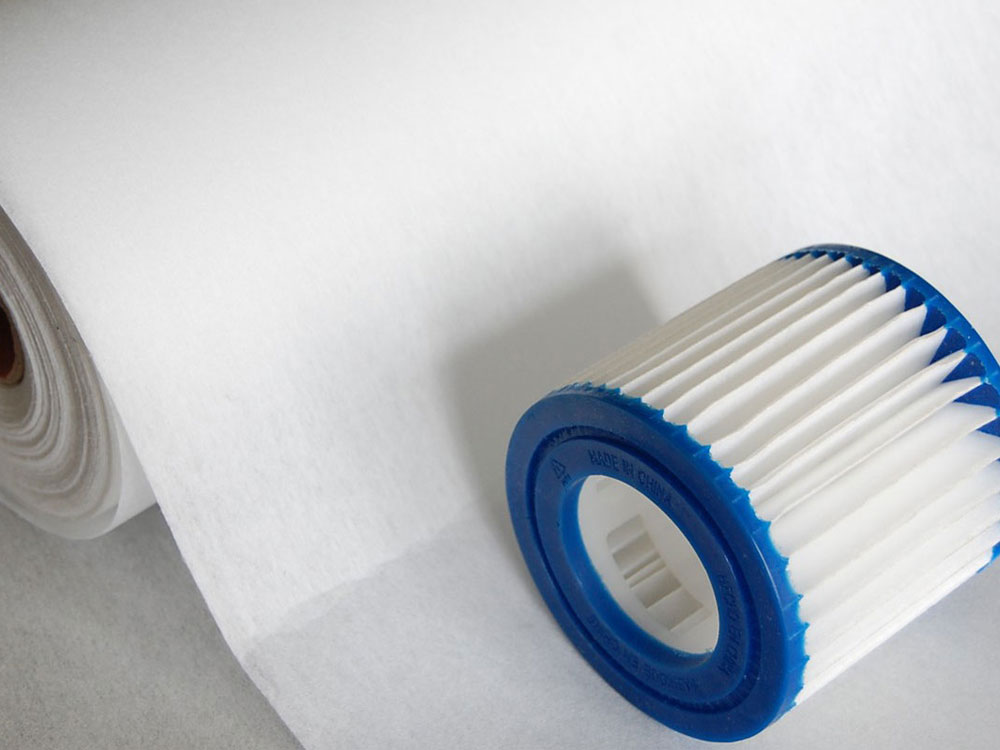

Filters, Radiators, etc,.

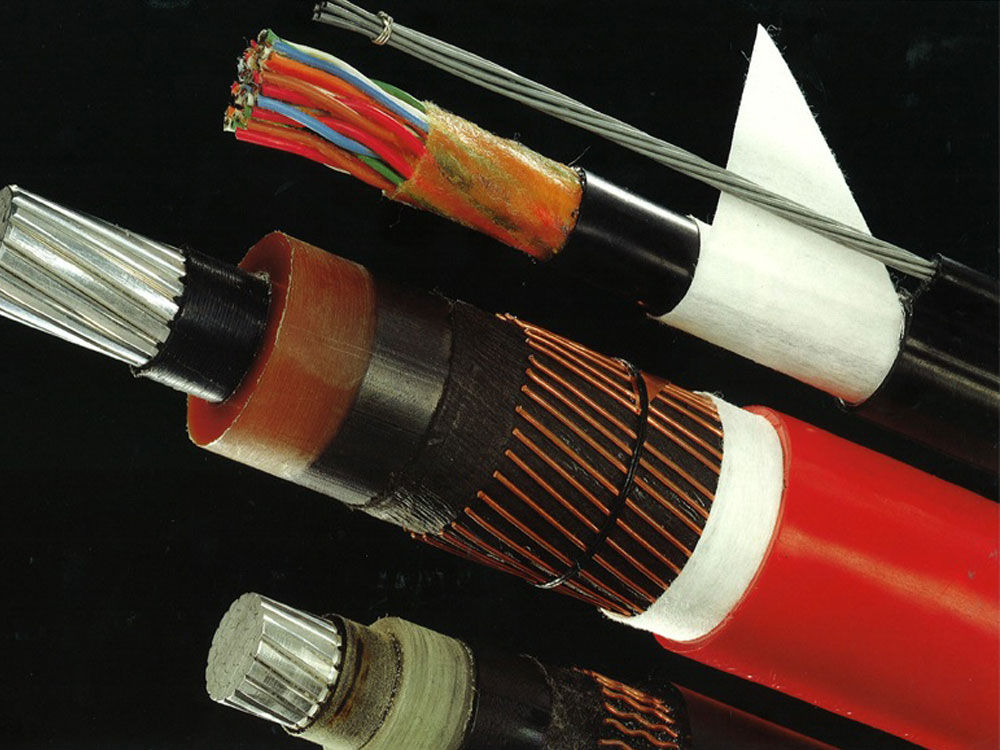

ELECTRICAL INDUSTRY

Electric Motor Winding Separators, Insulators, etc,.

How to choose Absorbent Products

CHOOSING BASED ON THE TYPE OF FLUIDS SPILLED

Oil, Fuels & hydrocarbon based applications.

When there is an oil or oil based spills then the white sorbents are the ones to use. White Sorbents also called as Oil Sorbents are hydrophobic in nature. They repel water and hence are a great choice for offshore based spill applications.

Aggressive, Unknown & Hazardous Chemical Applications.

If you are handling, aggressive or unknown chemical fluids, then the chemical sorbents which are generally yellow or pink in colour are the ones to use.

Coolants, Oils, water and solvent Based applications.

If you’re likely to spill a mixture of liquids such as degreaser, water-based chemicals, coolants or small amounts of oils and fuels, then the grey general purpose absorbents are most suitable. These sorbents are hydrophilic in nature which makes them absorb water as well.

Choosing Based On Type Of Application

Absorbent Pads

Pre-cut for easy use. Ideal for cleaning up smaller spills or for final clean.

Absorbent Rolls

Available in various lengths. Cut to place on workbenches, on shelves or Under machinery.

Absorbent Socks

Absorbent Spill socks are ideal for use under large vehicles to catch leaks and drips.

Absorbent Pillows

Use to Absorb larger block drains and catch drips.

Absorbent Booms

Absorbent Booms are larger than socks , these are ideal for shoreline clean-up of oils and can absorb a large quantity of oil at once.

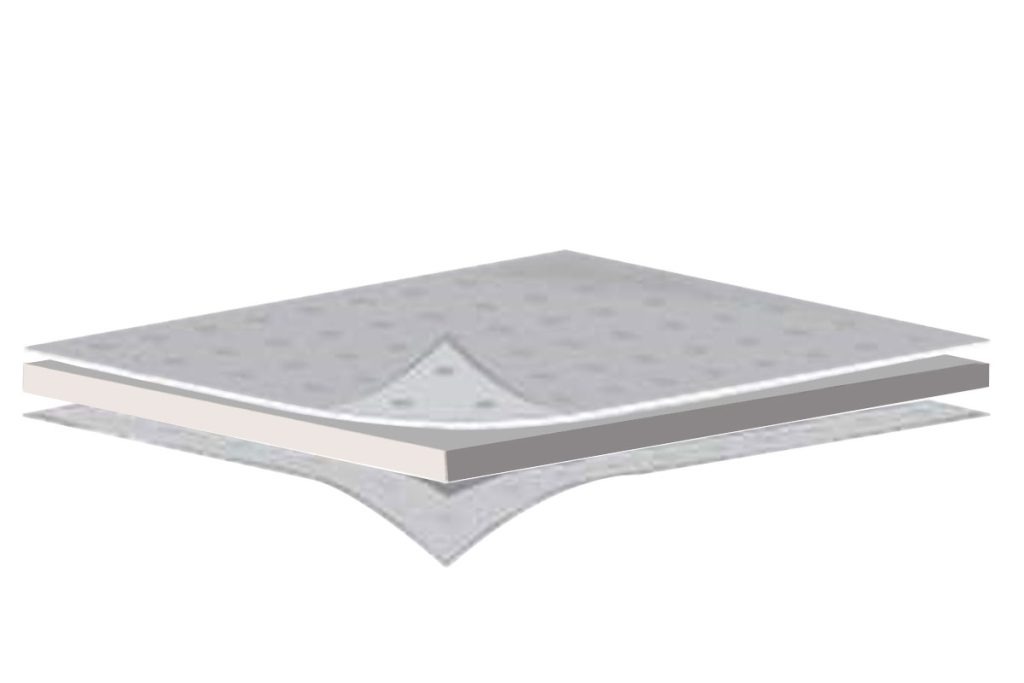

Choosing Based On Type Of Construction

Non Bonded / Meltblown

In this Construction the polypropylene Fibres that are blown in one pass and do not feature any sonic bond points. This make the fabric slightly more absorbent but it also makes the sheet less durable, and more prone to linting due to lack of sonic bond points.

Spun bound – Meltblown (SM)

The Spun bound Meltblown construction like its name suggests is actually where we sonically attach a thin layer of ‘no –lint’ spun-bond material onto the top surface of the absorbent. This reduce the linting and considerably durability , which is important where foot traffic is concerned.

Spun bound –Meltblown –Spunbound (SMS)

This construction features an absorbent core that Is put between two non – linting, extra durable , spun –bond cover sheets. This variant is the best for strength and results In an absorbent which gives virtually no –linting at all. It is however a point of caution that foot traffic should be avoided due to its slippery construction.